Blog

-

01.12.2012

-

Category: Blog C

-

Hits: 128

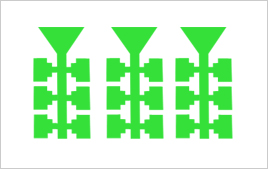

The wax patterns are assembled onto runners and into a finished tree which is ready to be dipped. Tree making is a very critical stage which will decide metal flow thus resulting the final quality of casting. Once tree is made it may be washed to remove any unwanted substance like dust, mould release agents etc.

-

26.09.2012

-

Category: Blog C

-

Hits: 267

Now the desired molten metal is poured into the pre-heated mold cavity. Using spectrometer we will make the required specification by addition of required material. Then cool it under room temperature before further process. Casting is the key step in the whole investment casting process.