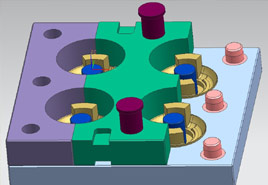

Materials for Special Applications & Custom Product Development

Our Research and Development people apply their in-depth knowledge, skills, and imagination to create improved design, materials, methods, and products. Our extensive research and testing capability is one more resource that helps us bring innovative ideas to the production floor. Whether it's exploring new ways to help you solve existing problems, or assisting you in developing proprietary products, we can produce answers and solutions that give you competitive advantages. Your product will reach market faster at lower costs.

Stainless Steel Casting

STAINLESS STEEL

We are very experienced in Stainless steel casting. With strong capability of casting Martensitic, Ferritic and Austenitic stainless steels. we manufacture custom Stainless Steel casting parts and components for industries and applications including automotive, food & dairy, machinery, medical, plumbing, watering, mining, petrochemical, electrical, energy etc. We can assure you high-quality stainless-steel castings. The weights of the stainless-steel casting parts are from few grams to 25Kgs. Typical tolerances are ± 0.5%.

DUPLEX & SUPER DUPLEX STAINLESS STEEL CASTING

We specialize in the customized production of Duplex and Super Duplex Stainless steel castings. Our manufacturing capability for these castings ranges from few grams to 25 kg a piece.

We maintain proactive communication with our customers to assure that we fully understand our customers’ requirements and produce parts with the desired characteristics in the most cost-effective manner.

Carbon Steel & Low-Alloy Steel Casting

CARBON STEEL CASTINGS

Carbon steel is one of main materials in steel casting industry. According to the carbon contents, carbon steels are classified as three types: Low-carbon steels(< 0.20% C): A range of tensile properties are provided by heat treatment, and may be hardened to provide high surface hardness with abrasion resistance and good core ductility.

Medium-carbon steels(0.20 to 0.50% C): This grade makes it more durable, pliable and stronger. A range of tensile strengths are possible, with good ductility and impact resistance, easy to for secondary machining in a softened state.

High-carbon steels(> 0.50% C): High strength, good shape memory, is a particularly good option for spring manufacturers. This alloy steel for high strength applications is subject to wear and abrasion and is also suitable for heavy duty applications.

LOW ALLOY STEEL CASTINGS

Low-alloy steels contain specified amounts of chromium, nickel or molybdenum to the carbon to enhance harden-ability and toughness. Low-alloy steels are most commonly used for components in the oil and gas, and pump and valve industries, but are also suitable for military vehicles and earth-moving and construction equipment. Common elements added carbon steels are Nickel (Ni), Chromium (Cr) and Molybdenum (Mo). Nickel is added to resist corrosion and provide strength, stability and toughness. Chromium is added to resist wear and corrosion and help the steel to increase strength and harden-ability. Molybdenum is added to withstand temperatures and elevate the strength and harden-ability of the steel.