Investment Casting Process

1. Tooling Making

Cathy Casting Company uses customer-supplied drawings or models to calculate wax and metal shrinkage, which helps design the appropriate tool. Experts review the geometry, advising on modifications such as radius and undercuts. The tool type is determined based on the design complexity, production quantity, and frequency of use.

7. Casting / Pouring

In the investment casting process, molten metal is poured into the pre-heated mold cavity. A spectrometer is used to analyze and adjust the metal's composition to meet required specifications. After solidifying at room temperature, the casting is a crucial step as it forms the final product with intricate shapes and precision.

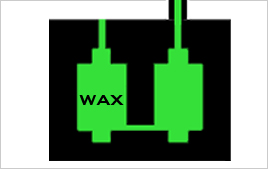

2. Wax Injection

Investment casting starts with creating a wax pattern of the finished part using a die. Melted wax is injected under high pressure into the die to form a replica. For low volumes, a simple die is used, while high volumes require complex multi-cavity dies. For rapid prototypes, foam or PLA can replace wax, but shrinkage calculations differ.

8. Shell Removal

After the casting has cooled and solidified, the ceramic shell is removed using an electric or pneumatic knockout mechanism. This mechanism applies force to break the ceramic shell, freeing the metal casting inside. It's an efficient method for separating the final casting from the surrounding ceramic material.

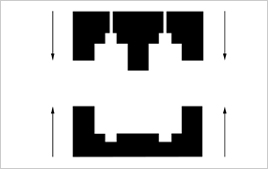

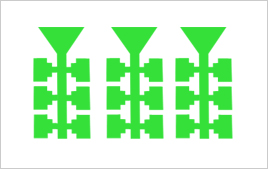

3. Wax Assembly

In investment casting, wax patterns are assembled onto runners to form a tree. Proper tree making is crucial as it affects metal flow and casting quality. After assembly, the tree may be washed to eliminate contaminants like dust and mold release agents before proceeding with the ceramic coating process.

9. Cut Off

After removing the ceramic shell, individual investment castings are separated from the central sprue. This process involves cutting or breaking the connections between the castings and the sprue, allowing the final products to be released and prepared for further finishing or assembly as needed..

4. Slurry Coating

In investment casting, the pattern assembly is dipped into a ceramic slurry, and the slurry adheres to the pattern's surface, gradually building a ceramic shell around it. This process is repeated to create a thick and durable ceramic mold that will later be used to cast the desired metal product.

10. Finishing

After casting, metal parts may have rough surfaces or excess material. Finishing processes like cutting, grinding, sandblasting, and machining are employed to achieve precise dimensions, smooth surfaces, and desired aesthetics, ensuring the castings meet the required specifications and functional requirements.

5. Stuccoing

Stuccoing refers to the process of applying a stucco or fine refractory powder onto the ceramic shell. It enhances the surface texture, improves mold strength, and helps achieve a smoother casting finish. Stuccoing is done after the ceramic shell is built, but before it is ready for the pouring of molten metal.

11. Inspection

Inspectors visually examine casting's external surface for cracks, shrinkage, porosity, and irregularities. Dimensional inspection uses tools like calipers, micrometers, CMM for precise measurements. Non-destructive testing (NDT) methods find internal defects without damaging the casting, including X-ray, ultrasonic, magnetic particle, liquid penetrant, and eddy current testing.

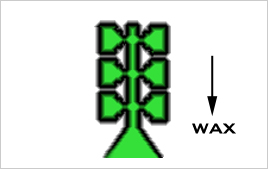

6. Dewaxing

In investment casting (lost wax casting), dewaxing is achieved using a steam-dewaxing autoclave or flash fire furnace. The ceramic shell mold is rapidly heated, melting and removing the wax through the gate. The firing process burns out all pattern material, preheats the mold, and prepares it for casting, resulting in intricate metal products.

12. Pack

After inspection, investment castings are carefully packed to avoid damage during transit. They may be wrapped in protective materials and placed in boxes or crates. The packed castings are then dispatched for delivery to customers or downstream processes.